Hazard Communication Standard Changes: The Must-Know Facts

The Hazard Communication Standard in 1983 gave workers the ‘right to know,’ but the new Globally Harmonized System gives workers the ‘right to understand.’

Are you sure you are providing the right training under the ‘Right To Understand’ Hazard Communication Standard?

- The specific criteria for classification of health and physical hazards: Hazard Classification.

- Manufacturers will be required to provide a label that includes a harmonized signal word, pictogram, and hazard statement for each hazard class and category. Precautionary statements must also be provided. Employees must be trained to understand these labels and pictograms.

- Safety Data Sheets will now have a specified 16-section format.

- Employers are required to train workers by December 1, 2013 on the new labels elements and safety data sheets format to promote recognition and understanding.

Find Out How Much You Can Save Instantly.

Try our on-line savings calculator.

Hazard Classification

There is now a uniform approach to communicating information about how to safely handle and use hazardous chemicals. This information, found on labels and safety data sheets, helps maintain consistency in the way hazard information is communicated. With a consistent method for providing easy to understand information, a safer environment is provided for workers.

Manufacturer Label

According to the Occupational Safety & Health Administration (OSHA) website, “Chemical manufacturers and importers will be required to provide a label that includes a harmonized signal word, pictogram, and hazard statement for each hazard class and category. Precautionary statements must also be provided.”

Training Requirements

December 1st, 2013 was the deadline for getting your team certified on the HazCom changes. While the deadline has come and gone, that doesn’t mean we can ignore these new regulations. After all, it’s not just about potential fines; it’s about everyone’s safety. The Hazard Communication Standard is in place to help keep everyone safe when working in a potentially hazardous setting or with hazardous materials. If you missed the deadline. Click here to get in compliance. The reason this training is required first is because as employees begin to see these new labels, pictograms and SDSs in their workplace, they need to understand what they mean in order to protect themselves from the dangers presented by chemical hazards.

Here are the training requirements for the revised Hazard Communication Standard.

- Employees now have the right to know and the right to understand information regarding hazardous chemicals they may be working with including pictograms and terms.

- MSDSs must be revised to the specified 16-section format for Safety Data Sheets

(previously Material Safety Data Sheets) - Label requirements for chemical manufacturers and importers including signal words and pictograms aligned with the Globally Harmonized System.

- Specific criteria must be used for classification of health and physical hazards.

- Employees must be trained in the new elements and formats by December 1, 2013.

- Employers and manufacturers must have a written plan for implementing the new requirements.

Safety Data Sheets

Training on the new 16-section format for Safety Data Sheets (previously Material Safety Data Sheets) must cover the following:

Section 1. Name/Identification

Section 2. Hazard(s) identification

Section 3. Composition/information on ingredients

Section 4. First-aid measures

Section 5. Fire-fighting measures

Section 6. Accidental release measures

Section 7. Handling and storage

Section 8. Exposure controls/personal protection

Section 9. Physical and chemical properties (lists the chemical’s characteristics)

Section 10. Stability and reactivity

Section 11. Toxicological information

Section 12. Ecological information*

Section 13. Disposal considerations*

Section 14. Transport information*

Section 15. Regulatory information*

Section 16. Other information, including the date of preparation or last revision

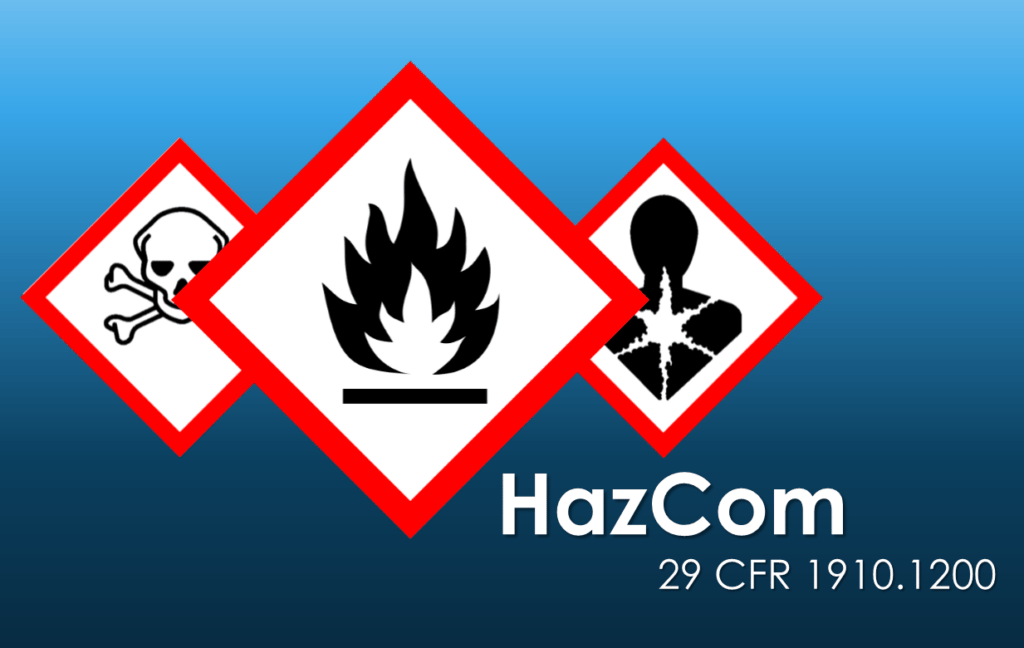

Pictograms

Pictograms are illustrations, specifically black, set against a white background with a diamond outlined in red. Each pictogram is designed to communicate particular health or safety hazards that a hazardous chemical might present. Just as almost everyone recognizes that a skull and crossbones on a label represents a hazard presented by a chemical, in time workers will become familiar with the other simple pictograms.

The 8 pictograms OSHA adopted include:

Health Hazard

Flame

Exclamation Mark

Corrosion

Exploding Bomb

Gas Cylinder

Flame Over Circle

Skull and Crossbones

What Stays the Same?

As was the case before, OSHA requires you to have a written Hazard Communication Program in your safety plans. You must continue to inventory and keep a list of all the hazardous chemicals in your workplace. Finally, you must inform your employees about hazardous chemical hazards in their workplace.

It is also important to note that while federal OSHA does not require annual HazCom training, HazCom training must be provided when a worker is first placed into a job with potential exposure to hazardous chemicals, when new hazardous chemicals are introduced, and other specific circumstances. However, certain states require annual “right-to-know” training. As a result it is considered a best practice to provide annual HazCom training.